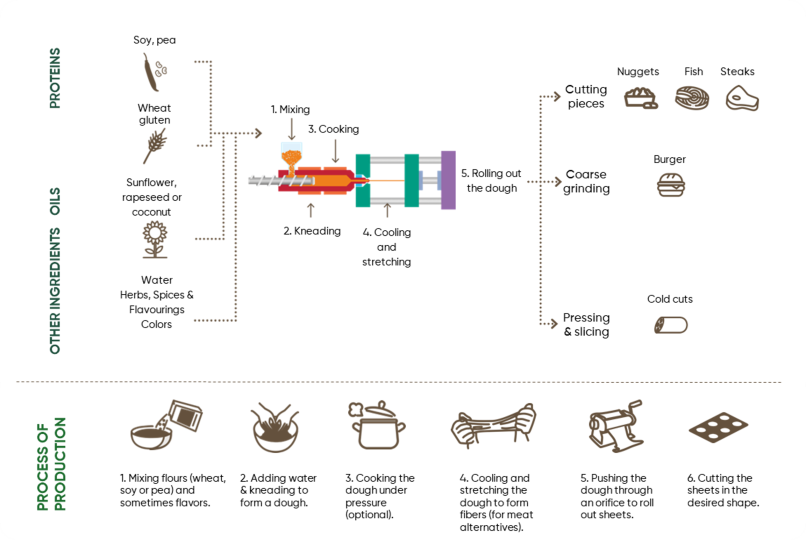

Explore the journey from ingredients to plant-based meat alternatives

Find out more about some of the key ingredients in plant-based meat alternatives and discover how we turn them into delicious products in six steps.

What is in the mix?

How we make our products

The production of plant-based meat alternative products can be explained in 6 main steps. In order to better understand these 6 steps, certain parallels can be drawn with the production of bread or pasta dough. This comparison is well outlined in the illustration below. The processes and equipment used are like those from a professional kitchen, however on a much larger scale.

Step 1: All ingredients, such as plant-based protein, water, salt, vegetable oils and other smaller ingredients are combined and mixed.

Step 2: This mixture is then kneaded until a smooth dough is formed.

Step 3: The dough is cooked under pressure.

Step 4: After cooking, the dough is cooled and then stretched. This process creates structures in the dough that are similar to the fibrous structures of meat.

Step 5: The dough is rolled out to make it ready for the final step.

Step 6: Depending on the desired shape of the end product, different techniques are used:

- For nuggets, large pieces are cut from the dough and coated afterwards.

- To make burger patties, the dough is coarsely grinded and then formed into a patty.

- To make sausage-shaped products, the dough will be shaped into a cylinder with the appropriate shape.

Finally, once the product has the right shape and size, it is frozen and packed, ready to be shipped.